Manifestation:

In a short period of time, the protective mirror is damaged and the burning point appears, and the protective mirror is a little damaged point on the glossy surface, showing black or white medium black spots

Cause analysis:

Due to the influence of process/technique/setting, the anti-slag is damaged, and the laser light is abnormal

solution:

- Appropriately increase the air pressure, usually the flow rate is not less than 15, the pressure is not less than 4, it is recommended to use the pressure gauge of oxygen is not less than 2 kg

- When welding, try to weld the gun and the plate at 45°, not vertically

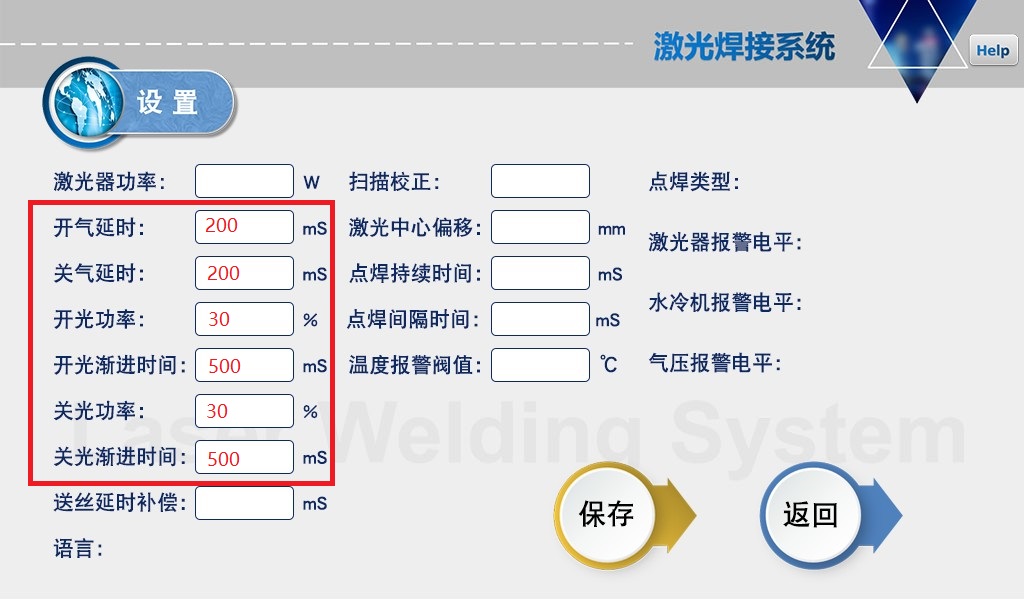

- Set the parameters as much as possible to give slow rise and fall, such as on/off gas delay 200-500ms, on/off optical power 20%, on/off light progressive time 200-300ms, as shown in the figure can not set 0

- When welding aluminum and galvanized sheet, this material will be more likely to damage the lens than other materials, and the minimum power welding should be used

- The quality of the protective lens also determines the durability of its use, and it is recommended to use original lenses

- At high power, the loss of the lens will increase compared to low power, which is an uncontrollable range

- When none of the above can be handled, F200 focusing lens + extended wide scale tube can be replaced to reduce splashing (additional purchase required)

Post time: 21-06-25