The version number of the panel monitoring page corresponding to the spot welding function is: 330 or above (inclusive)

I. How to use spot welding function

1.1 Home Enable spot welding mode

1.2 Select the type of spot welding inside the setting (fish scale/break)

1.3 Settings Set reasonable spot welding duration and spot welding interval

Two. Spot welding type parameters and debugging

First, use continuous welding to debug the process, and then select the spot welding type by enabling the spot welding function

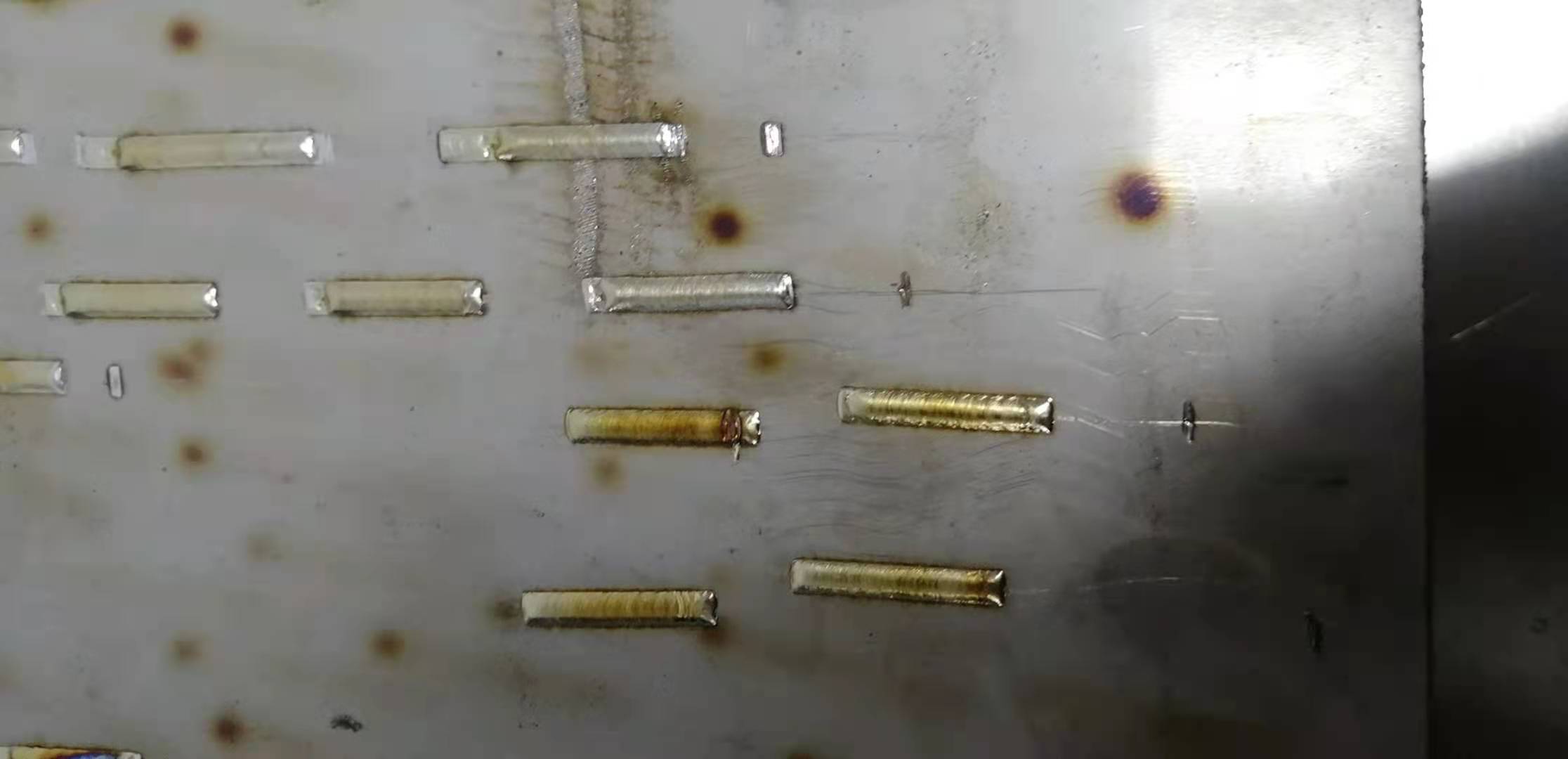

2.1 Fish scale mode welding

(In this mode, only the laser is turned off during the interruption, and other parameters such as switching/switching time do not affect or take effect)

Just set the spot welding duration and interval time to produce fish scale welding effect, the minimum can be set 1ms)

case

Spot welding duration: 150ms (this parameter affects the grain size of the weld)

Spot welding interval time: 50ms (This parameter affects the interval between the two grooves)

2.2 Intermittent mode welding

In this mode, the laser is turned off, the protective gas is turned off, and the wire feed is stopped. Other parameters such as on/off light time are also affected. Mainly used for fixed length welding)

Change the welding length by setting the spot welding duration, and the spot welding interval can be set higher

case

Spot welding duration: 1000ms (this parameter affects the welding length, that is, the time of the light)

Spot welding interval: 5000ms (This parameter can be fixed, the default is 5000)

Please note that in this mode, human judgment is required to lift the broken wire in time

Post time: 28-06-25