In industrial production processes, operations such as welding, cutting, spraying, and injection molding generate significant amounts of fumes containing dust and toxic gases. These fumes not only corrode production equipment and compromise product quality but also pose severe hazards to operators’ respiratory and nervous systems, potentially triggering mass health incidents. As the core equipment for controlling industrial fume pollution, the selection of industrial fume purifiers directly determines both pollution control effectiveness and production operating costs. Faced with a market flooded with diverse products boasting varying specifications, focusing on five essential metrics—fan airflow, purification efficiency, energy efficiency ratio, safety, and noise level—enables precise selection of cost-effective equipment that meets production requirements.

I. Fan Airflow: The “Power Core” of Purification Capacity

Fan airflow serves as the key parameter measuring a fume purifier’s “capture capability,” typically measured in cubic meters per hour (m³/h). . Insufficient airflow prevents timely extraction of fumes generated in production areas, even with sophisticated filtration systems, leading to fume dispersion throughout the workshop and creating a paradoxical situation where purification simultaneously causes pollution. Conversely, excessive airflow wastes energy and may impair filtration efficiency due to accelerated airflow.

When selecting equipment, comprehensive calculations must account for the production area’s size, smoke generation volume, and pollution concentration. For example: – Welding stations under 100m² with low smoke output: Recommend units with 800-1200m³/h airflow. – Large spray booths or multi-station concentrated pollution zones: Require medium-to-high airflow models exceeding 2000m³/h.

II. Purification Efficiency: The Core Metric for Pollutant Removal

Purification efficiency serves as the primary indicator for evaluating a fume purifier’s effectiveness, typically expressed as a percentage (%). For different pollutants—such as dust, VOCs (volatile organic compounds), and toxic gases—corresponding filtration efficiency parameters must be considered. For instance, high-efficiency HEPA filters should achieve ≥99.97% filtration efficiency for particulate matter (0.3μm diameter) in welding fumes. For VOCs in spray exhaust, focus on activated carbon filters’ iodine value (typically ≥800mg/g)—higher iodine values indicate stronger adsorption capacity for organic pollutants.

III. Energy Efficiency Ratio: The “Cost Code” of Green Production

The energy efficiency ratio (unit: m³/(h·W)), calculated as “fan airflow ÷ rated power,” is a key indicator of a fume purifier’s energy-saving performance. A higher value indicates lower electricity consumption per unit volume of purified air, resulting in reduced long-term operating costs.

IV. Safety Metrics: The Lifeline of Production Operations

Industrial fume purifiers often operate in high-temperature, high-dust, and high-voltage environments. Substandard safety performance can easily lead to fires, electric shocks, or equipment damage. National regulations clearly define safety requirements for industrial purification equipment. Key safety configurations to verify during procurement include:

Electrical Safety: Equipment must feature overvoltage/undervoltage protection, overcurrent protection, and leakage protection to prevent short circuits caused by aging wiring.

Fire Safety: For high-temperature fume scenarios like welding, the purifier’s air inlet should be equipped with a “fireproof mesh,” and internal filters must use flame-retardant materials to eliminate fire hazards.

Operational Safety: Equipment must display clear operational labels. Filter replacement mechanisms should incorporate a “power-off lockout” function to prevent operators from accessing internal components while energized, thereby reducing electric shock risks.

V. Noise Levels: The “Invisible Guardian” of Workshop Environments

Noise pollution in industrial workshops is often overlooked. Yet prolonged exposure to high noise levels not only compromises operators’ hearing health but also diminishes work efficiency and may even cause occupational noise-induced hearing loss.

The primary noise source in fume purifiers stems from fan operation. High-quality equipment employs a “triple noise reduction design” to control noise: First, utilizing low-noise fans (such as centrifugal fans, typically operating below 65 decibels); second, installing “vibration damping pads” between the fan and the equipment housing to reduce vibration noise; third, incorporating “sound-absorbing cotton” inside the equipment to absorb noise generated by airflow. During procurement, it is recommended to conduct on-site testing of operational noise levels (measured at a distance of 1 meter from the unit while it is running normally). Prioritize products with noise levels ≤65 dB. If the workshop contains precision instruments or processes sensitive to noise, select low-noise models with noise levels ≤60 dB.

Selecting an industrial fume purifier is not merely about “purchasing a piece of equipment”; it is a crucial step for enterprises to fulfill environmental responsibilities, safeguard employee health, and control operational costs. During the actual procurement process, we recommend thorough communication with manufacturers to develop a customized purification solution.

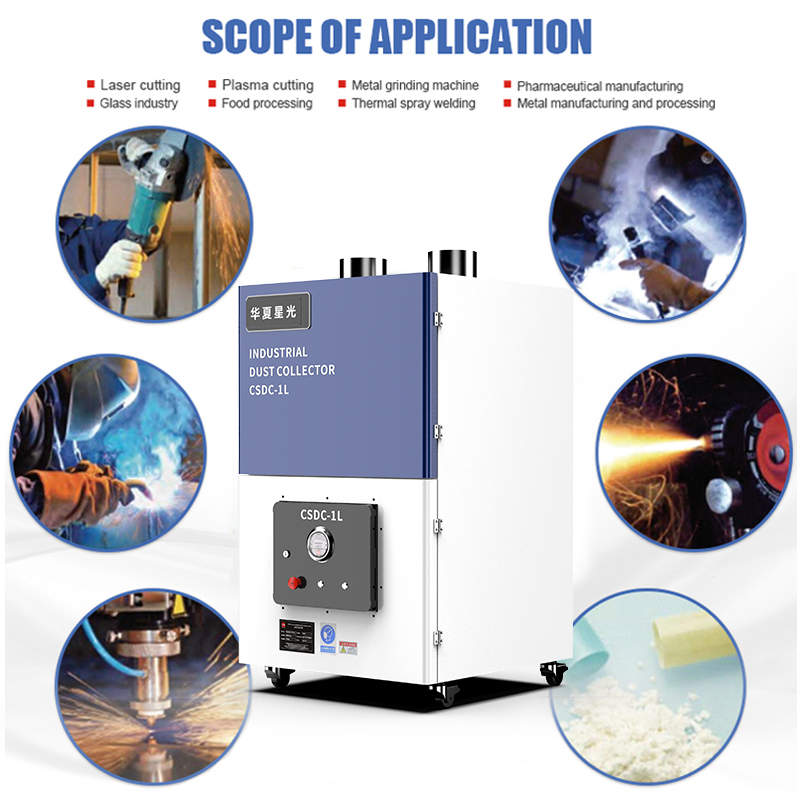

As a company specializing in industrial fume control, Huaxia Starlight brings over 16 years of industry experience to provide tailored fume purification solutions for diverse sectors, including automotive manufacturing, machining, electronics, and spray coating. Our products carry CE certification and are backed by a comprehensive after-sales service system—from equipment selection and installation commissioning to filter replacement and regular maintenance, our professional technical team provides end-to-end support. Should you encounter any issues during your selection process, feel free to consult us anytime. We will leverage our expertise and rigorous approach to deliver one-stop pollution control services, helping your enterprise achieve the goals of “green production and efficient operations.”

Post time: 10-10-25