The cartridge dust collector is a type of dust collector composed of cartridges as the filtering element and using pulse jet. The structure of the cartridge dust collector consists of an air inlet pipe, an air outlet pipe, a box body, a ash hopper, a cleaning device, a deflector, an air flow distribution plate, cartridges and an electrical control device, similar to the structure of the air box pulse bag dust collector.

The working principle of the cartridge dust collector is that the dusty exhaust gas, guided by the fan, enters the dust collector through the air duct. Due to the sudden expansion of the gas flow end face and the effect of the gas flow distribution plate, some coarse dust particles in the gas flow settle into the ash hopper under the action of gravity and inertial force. Fine and low-density dust particles enter the filter chamber. Through the combined effects of Brownian diffusion and fiber interception, the dust deposits on the surface of the filter material in the filter cartridge. The purified gas then enters the clean air chamber of the filter cartridge dust collector and is discharged from the air outlet by the fan.

As the dust collector operates, the dust layer isolated on the outer surface of the filter cartridge becomes thicker and thicker, and the resistance to equipment operation increases. When the system detects that the resistance has reached the set value of the equipment, the filter cartridge dust collector automatically starts the reverse blowing system. High-pressure gas flow is blown into the interior of the filter cartridge through the pulse valve, creating an instantaneous positive pressure inside the filter cartridge and generating a huge vibration. This causes the dust deposited on the filter material to fall off and drop into the ash hopper. The collected dust is discharged into the ash cartridge through the ash discharge valve. This ash cleaning process is carried out online. The filter cartridge dust collector does not need to be shut down and does not affect production. It is widely used in dust removal, material recovery and air filtration in industries such as tobacco, medicine, food, building materials, metallurgy, casting, chemical engineering, power and machinery.

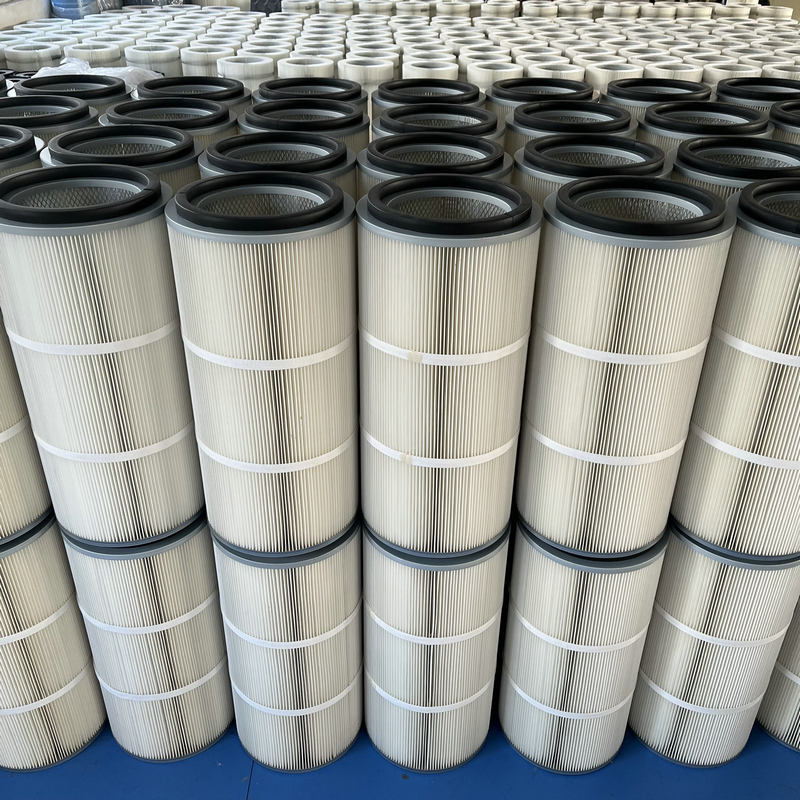

The filter cartridge dust collector of our company has a high purification efficiency, with a purification rate of over 99.9% for dust particles larger than sub-microns. The equipment has low operating resistance, effectively saving the energy consumption of the dust removal system, and the filter cartridge replacement is more convenient. For general dust, the filter cartridges can be used for a long time without replacement, eliminating the cumbersome work of frequently changing and washing the filter bags required by commonly used bag-type dust collectors and saving a large amount of maintenance costs. The cartridge dust collector adopts a modular combination, and its size can be freely selected. It can expand the original combination and add dust removal units without making too many changes to the original equipment.

Post time: 04-01-26