Easy-Maintenance High-Temperature Nanofiber Filter Cartridge Dust Collector Pulse Jet Cartridge Dust Collector for Welding Fume

Main Advantages

High – efficiency Filtration: Filter cartridges have a high filtration efficiency, capable of effectively capturing dust particles in the micron range. The filtration efficiency for dust particles larger than 0.3μm can reach over 99%, meeting strict environmental protection emission standards.

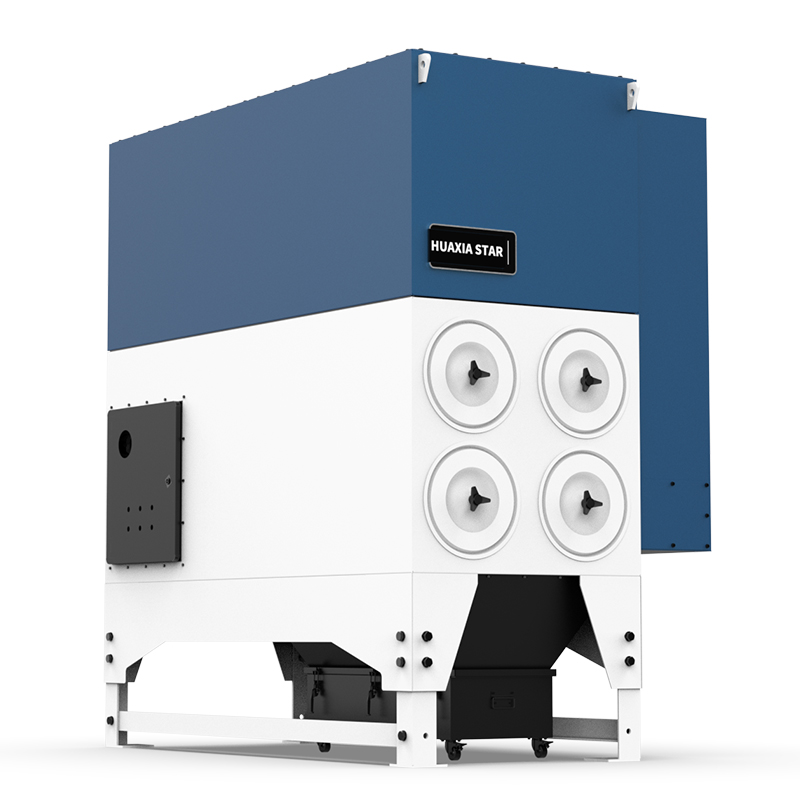

Compact Structure: Compared with traditional bag – type dust collectors, cartridge dust collectors occupy less space. The arrangement of filter cartridges is more compact, saving installation space, especially suitable for industrial sites with limited space.

Convenient Maintenance: Replacing filter cartridges is relatively simple and quick, reducing the maintenance workload and downtime. At the same time, the high degree of automation of the dust – cleaning system reduces the cost of manual maintenance.

Long Service Life: High – quality filter cartridge materials and a reasonable dust – cleaning design contribute to a relatively long service life of the filter cartridges, usually ranging from 1 to 3 years. This reduces the frequency of filter media replacement and operating costs.

Strong Adaptability: According to different industrial production conditions and dust characteristics, cartridge dust collectors with different materials, filtration accuracies, and dust – cleaning methods can be selected, making them suitable for various industries such as machining, metal smelting, chemical industry, cement, and food.

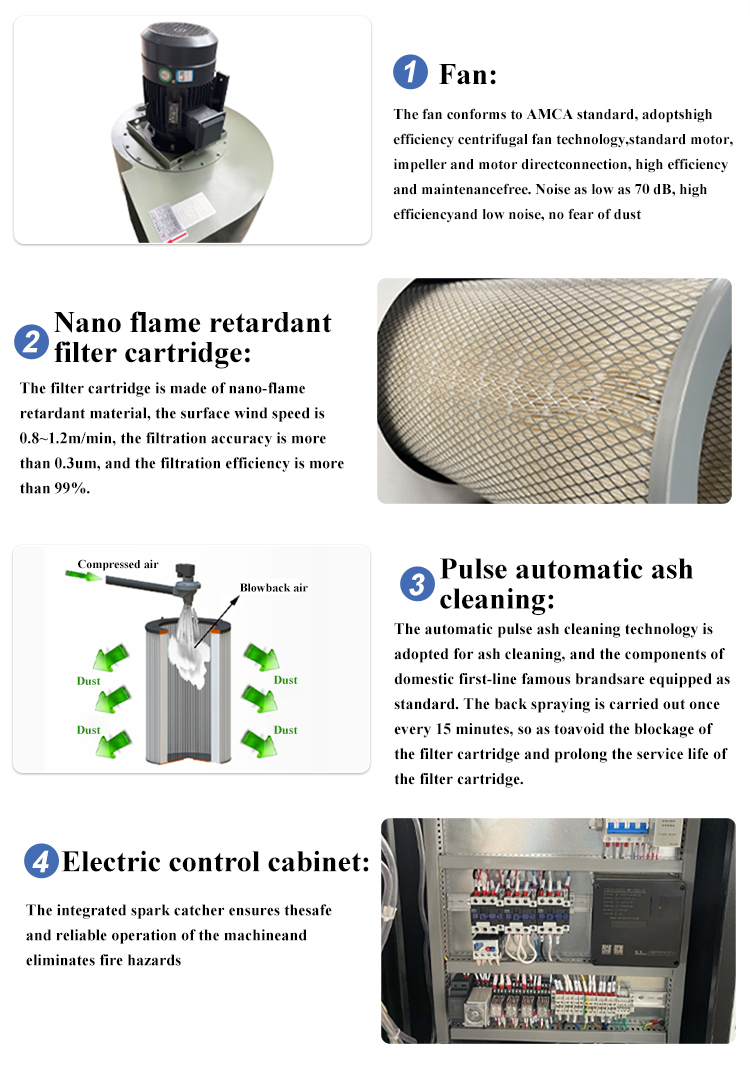

Key Components

Filter Cartridges: These are the core components of the dust collector, typically made from materials like filter paper, synthetic fibers, or other filtering substances. Filter cartridges often feature a pleated design, which increases the filtering area within a limited space, enhancing both the filtration efficiency and dust – holding capacity. Common cartridge materials include glass fiber and polyester fiber. In some special working conditions, nanofiber filter cartridges are used, offering better filtration performance and longer service life.

Dust – cleaning System: To ensure the continuous and stable operation of the filter cartridges, the dust accumulated on their surfaces needs to be removed in a timely manner. Common dust – cleaning methods include pulse – jet cleaning and reverse – air cleaning. In pulse – jet cleaning, compressed air is released instantaneously, causing the filter cartridges to vibrate and shake off the dust. Reverse – air cleaning, on the other hand, uses a reverse airflow to blow off the dust from the cartridge surface.

Housing: It is used to accommodate components such as filter cartridges and the dust – cleaning system, providing a space for the flow of dusty gas. The housing is generally made of high – quality steel plates through welding, with good sealing performance and strength, capable of adapting to different industrial environments.

Inlet and Outlet: The inlet is where the dusty gas enters, and the outlet is where the clean gas is discharged. Reasonable design of the shape, size, and location of the inlet and outlet helps to optimize the air distribution and improve the dust – collection efficiency.

Control System: It monitors and controls the operation of the dust collector, including setting and adjusting parameters such as the dust – cleaning cycle, dust – cleaning time, and the operating status of the fan, ensuring the efficient and stable operation of the dust collector.

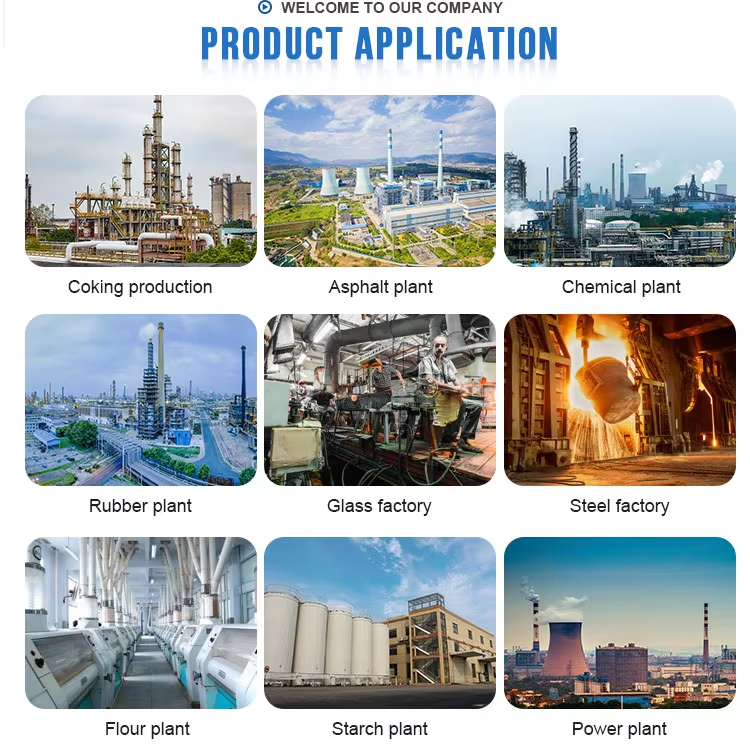

Application Scope

Machining Industry: During metal cutting, grinding, polishing, and other machining processes, a large amount of metal dust and swarf are generated. Cartridge dust collectors can effectively collect these pollutants, improving the workshop working environment, protecting workers’ health, and avoiding equipment wear caused by dust.

Chemical Industry: In the chemical production process, such as in the conveying, mixing, and packaging of powder materials, various chemical dusts and harmful gases are produced. With suitable filter materials and pretreatment devices, cartridge dust collectors can effectively treat these pollutants and ensure compliance with emissions standards.

Cement Industry: During the production, transportation, and storage of cement, a large amount of cement dust is generated. Cartridge dust collectors can be installed at the dust – generating points of equipment such as crushers, mills, and packers to collect dust and reduce the pollution of dust emissions to the atmospheric environment.

Food Industry: In the food processing process, such as flour processing, baking, and confectionery production, dusts like flour and sugar powder are produced. Cartridge dust collectors can be used to collect these dusts, ensuring the cleanliness of the food production environment and preventing dust from contaminating food.