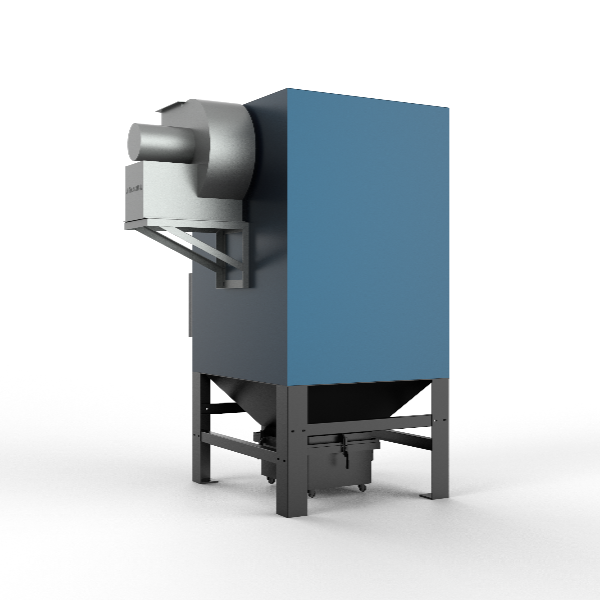

Short Lead Time for Jet Vortex Cone Dust Collector - Industrial Pulse bag Dust Collector for Stone Crusher – Star

Short Lead Time for Jet Vortex Cone Dust Collector - Industrial Pulse bag Dust Collector for Stone Crusher – Star Detail:

Parameters

|

ITEM |

DETAIL |

| Model name | CSDC-12L |

| Fan power | 15KW |

| Handling air volume | 7500-8000 M3/H |

| Number of filter cartridges | 12 |

| Filter area | 276 M2 |

| Filter material | Nano flame retardant filter material |

| Cleaning method | Pulse automatic cleaning |

| Noise | <=80DB |

| Compressed air | 0.5-0.6Mpa |

| Power supply | 380V/50HZ |

| Dimension(L*W*H) | 2180*1350*3580 |

| Total Weight | 1400KG |

Structures

Features

1. The high-efficiency filter element inside the filter cartridge dust collector adopts a pleated cylindrical structure design. Compared with the traditional bag filter cartridge, it has a higher density and a compact structure, reducing the equipment footprint; in terms of installation and later maintenance Work has been reduced.

2. In the case of the same volume of the filter cartridge filter and the bag filter, the filter area of the filter cartridge filter is much larger, and the filter cartridge inside the filter cartridge filter is installed vertically on the ceiling of the filter cartridge, and the filter cartridge is dedusted. During the use of the device, the resistance is small, the air inlet and the air outlet are connected with ventilation pipes, and the filtration efficiency is as high as 99.7%.

3. The inner filter cartridge of the filter cartridge dust collector adopts imported polyester film-coated filter paper, with sub-micron filtration precision, which can effectively purify dust particles below 0.3 microns. The performance of the filter material is stable and easy to replace.

4. The filter paper pleated cylindrical equipment not only greatly increases the filtering area, but also makes the structure more compact when installed in the filter chamber of the dust collector, and the fixed chuck design is easy to replace and disassemble.

5.The design of the pulse jet cleaning method of the filter cartridge dust collector is controlled by the pulse controller, and the normal operation of the equipment is not affected during the cleaning period, which ensures the long-term continuous and efficient operation of the filter cartridge dust collector.

Application

Widely used in the purification of dusty gas and the recovery of dusty materials in food, pharmaceutical, feed, metallurgy, building materials, cement, machinery, chemical industry, electric power, and light industry.

Samples

Product detail pictures:

Related Product Guide:

We also provide item sourcing and flight consolidation solutions. We have now our very own manufacturing facility and sourcing place of work. We could provide you with nearly every kind of merchandise associated to our merchandise variety for Short Lead Time for Jet Vortex Cone Dust Collector - Industrial Pulse bag Dust Collector for Stone Crusher – Star , The product will supply to all over the world, such as: Iraq, Sudan, Czech republic, We have more than 200 staff including experienced managers, creative designers, sophisticated engineers and skilled workers. Through hard work of all employees for the past 20 years own company grew stronger and stronger. We always apply the "client first" principle. We also always fulfill all contracts to the point and therefore enjoy excellent reputation and trust among our customers. You are very welcome to personally visit our company.We hope to start a business partnership on the basis of mutual benefit and successful development . For more information please do no hesitate to contact us..

The factory can meet continuously developing economic and market needs, so that their products are widely recognized and trusted, and that's why we chose this company.