Portable Desktop Silver Gold YAG Pulse 60W 150W 200W Mini CCD Jewelry Welding For Chromium Nickel Titanium

What can portable welding machine do?

— This welder is specially developed for laser welding of jewelry and mainly used in perforating and spot welding of gold and silver jewelry. The laser spot welding is an important aspect of laser process technology application. The spot welding process is thermal conduction, The laser radiation heats the surface of work piece,and the surface heat diffuse to the interior through thermal conduction and melts the work piece by controlling the width, energy, peak power and repeating frequency of laser- pulse to form specific molten pool. Because of its unique advantage,it is widely used in the process of gold and silver jewelry and welding of mini and small parts

Main Features

1. Observation system: The observation system of this jewelry spot welding machine is composed of a microscope and a built-in high-definition CCD camera. Users can choose one or two of them as the observation method according to their needs. Both can clearly observe the welding position of the workpiece, which is convenient for welding.

2. Adjustment of the CCD cross cursor: If the light spot is not in the center of the cross cursor in a very clear position of the CCD camera system, you can change the position of the cross cursor by clicking the middle position of the four sides of the screen, so that the welding spot is at the center of the cursor

3. For welding operation, first make sure that the machine has been turned on normally, put the workpiece into the sight range of the observation system, and then slowly move to the clearest position of the observation system.

4. Point the cursor at the desired welding position, gently step on the foot switch, the machine has a laser output for welding.Parameter adjustment, focus adjustment, after the first welding, the welding effect of the welding point does not meet the requirements, and the parameters need to be adjusted again. The focus (-3.0-+3.0) is adjusted to make the welding effect meet the requirements, and the welding will not be repeated later. Need to be adjusted again.

|

Laser wavelength

|

1064nm

|

|

Maximum laser power

|

150W

|

|

Maximum laser pulse energy

|

45J

|

|

Pulse width

|

0.1-15.0ms

|

|

Pulse frequency

|

1.0-15.0Hz graded adjustable

|

|

Aiming and positioning

|

Microscope + CCD camera system

|

|

Adaptable to welding

|

All kinds of metal jewelry welding, repairing

|

|

Host power consumption

|

≤2.8KW

|

|

Power demand

|

220V±5% ,50HZ

|

|

Cooling method

|

Water circulation air-cooled

|

|

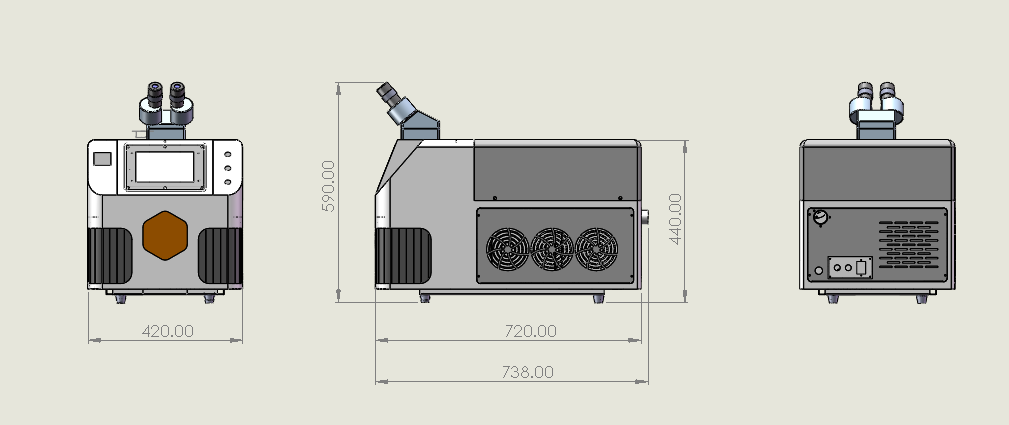

Dimensions of the host (L*W*H)

|

720×420×590mm

|

|

Machine weight

|

50 kg

|

|

Ambient temperature

|

≤30℃

|

Application of Laser welding machine:

Jewelry laser spot welding machine is widely used in aviation, aerospace, sporting goods, jewelry, golf clubs, medical equipment, aluminum alloy dentures, instrumentation, electronics, machining, automotive and other industries, in particular for the hole of gold and silver jewelry, Spot welding seams, inlaid force pieces and claw foot parts and other welding