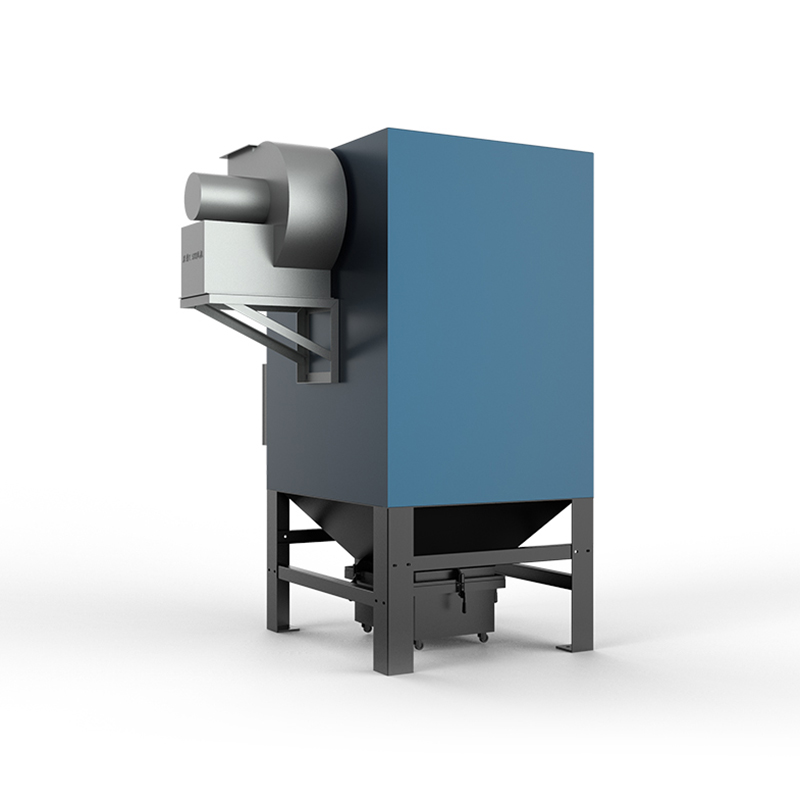

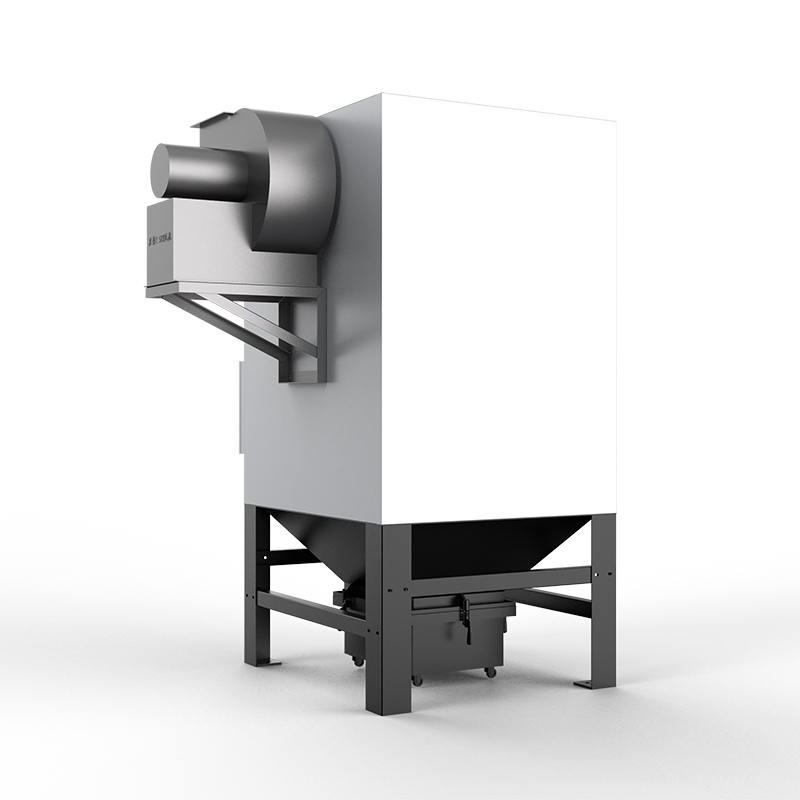

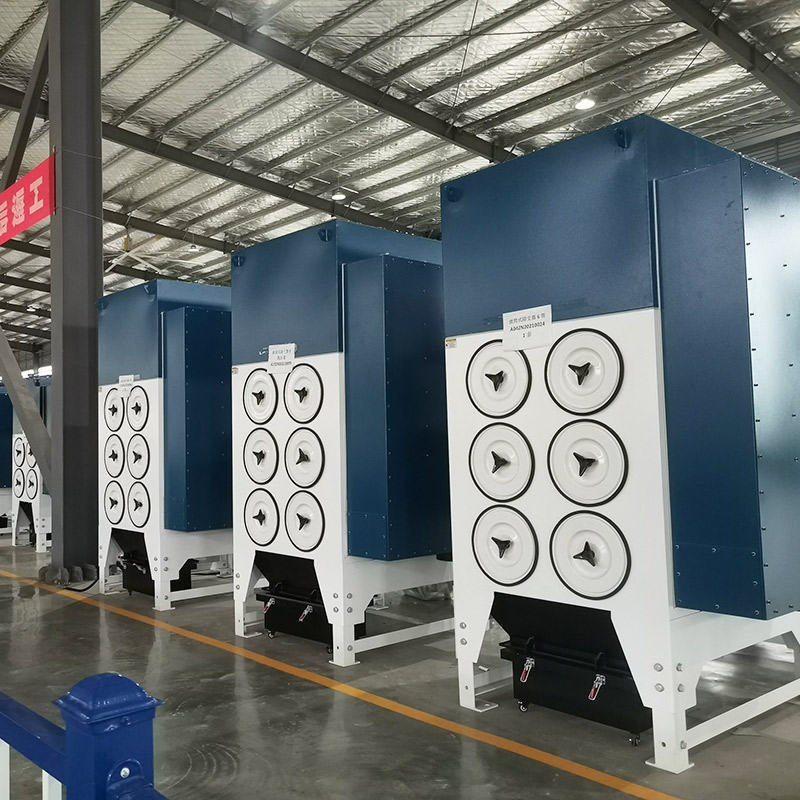

Pulse Jet Industrial Bag Type Baghouse Dust Collector

How does it work?

The high dust removal efficiency of the bag filter is inseparable from its dust removal mechanism. When the dust-laden gas enters the ash hopper from the air inlet pipe at the lower part of the precipitator and enters the ash hopper through the deflector, due to the collision of the deflector and the reduction of the gas velocity, the coarse dust will fall into the ash hopper, and the remaining fine particles will follow the gas. When entering the filter bag room, due to the inertia, diffusion, blocking, hooking, static electricity and other effects of the filter material fibers and fabrics, the dust is retained in the filter bag, and the purified gas escapes from the bag and is discharged through the exhaust pipe. The ash deposits on the filter bag are removed by gas backwashing, and the removed dust goes down to the ash hopper, and is discharged to the ash conveying device through the double-layer ash discharge valve. The dust on the filter bag can also be removed by the method of jet pulse air flow, so as to achieve the purpose of cleaning the dust, and the removed dust is discharged by the ash discharge device. The high dust removal efficiency of the bag filter is also inseparable from the filter material. The performance and quality of the filter material are directly related to the performance and service life of the bag filter. The filter material is the main material for making filter bags, its performance and quality are to promote the progress of bag dust removal technology and affect its application range and service life.

What are its advantages?

(1) The dust removal efficiency is high, generally above 99%, and the dust concentration in the outlet gas of the dust collector is within tens of mg/m3, which has a high classification efficiency for fine dust with sub-micron particle size.

(2) The range of air volume to be treated is wide, the small one is only a few m3 per minute, and the large one can reach tens of thousands of m3 per minute.

⑶ Simple structure, easy maintenance and operation.

⑷ On the premise of ensuring the same high dust removal efficiency, the cost is lower than that of the electrostatic precipitator.

⑸ When using glass fiber, polytetrafluoroethylene, P84 and other high temperature resistant filter materials, it can operate under high temperature conditions above 200 ℃.

⑹ It is not sensitive to the characteristics of dust and is not affected by dust and resistance.

What is the current state of the market for it?

The market of various countries has huge demand for bag filter, dust filter material, especially high temperature fiber filter material has broad market development prospects. my country's "Twelfth Five-Year Plan" has put forward higher demands for environmental protection. Water, gas, sound, and slag will be more applied to filter materials, and the market prospect of the filter material industry is promising. Among them, in the field of smoke and dust control, the bag type dust collector is more and more widely used at home and abroad due to its high dust removal efficiency, will not cause secondary pollution, and facilitate the recovery of dry materials, accounting for 80% of the dust removal equipment used. The iron and steel industry is one of the main sources of air pollution. my country's steel production has exceeded 300 million tons. According to Baosteel's application of bag-type dust removal, it needs 21 million square meters. After conversion, 6 million square meters of filter material are replaced every year.