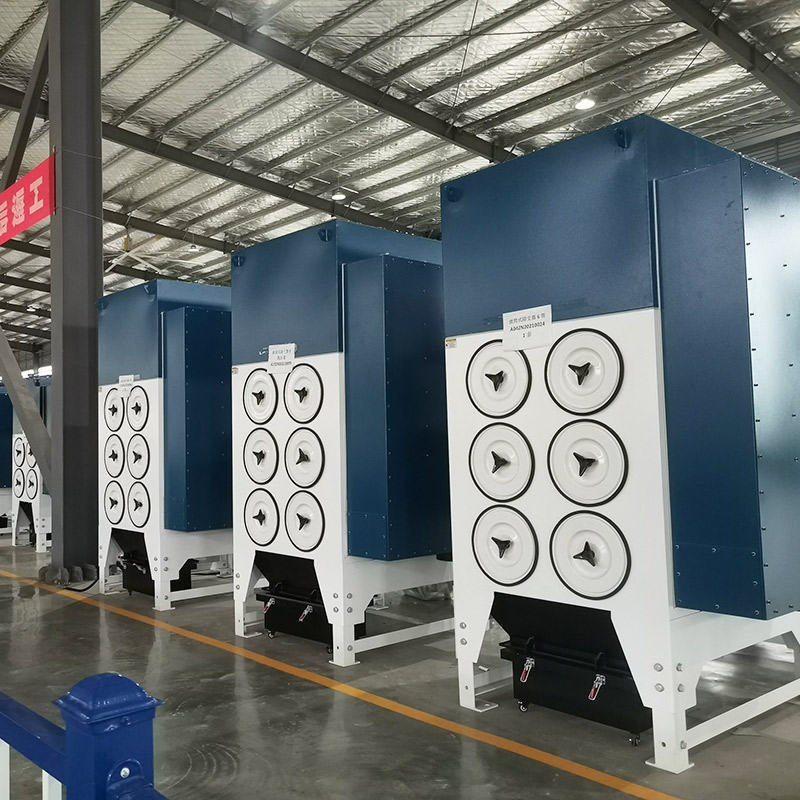

Grinder Dust Collector for metal Dust Grinding and Dust Removal Platform

About our product features?

The air inlet of the exhaust workbench is equipped with a deflector to prevent the dust from directly impacting the filter element, thereby prolonging the service life of the filter element.

The fan adopts high-efficiency centrifugal fan, which has the characteristics of high efficiency and stable operation.

It integrates the function of workbench and dust removal, and directly removes the dust on the dust source.

The structure is compact, the floor area is small, and it can work at the same time in double or multi-station.

The filter media can be selected according to the nature of the dust to meet the removal of different types of dust.

The filter element has long service life, stable performance and easy replacement.

There are air inlets at the bottom, front and top of the workbench, which can effectively control the scattering of dust.

Pulse backflushing automatically cleans dust to ensure that the equipment is always in good working condition. The drawer type dust box is quick and convenient for dust removal.

How it works

1. The dust enters the purification and dust removal workbench under the suction of the centrifugal fan. Large particles of dust settle into the dust collection drawer by gravity. The remaining small particle dust passes through the filter cartridge of the purification and dust removal workbench and is blocked in the filter element. On the outer wall, the clean gas is discharged into the surrounding air through the fan, so that the dust-containing gas can be effectively purified.

2. After long-term use, more and more dust adheres to the outer surface of the filter element, and the resistance increases, resulting in a significant decrease in air volume. At this time, the pulse cleaning device is activated, the filter cartridge is reversely cleaned, and compressed air is used. Power on, the dust on the outer wall of the filter cartridge is shaken off and collected in the dust collection drawer, so as to ensure the smooth use of the filter cartridge for a long time and achieve a stable dust collection effect.